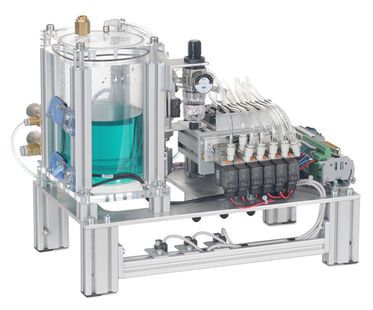

IPA FILLING STATION

Bottle filling:

The IPA filling station is mounted on a conveyor belt and allows an accurate filling of bottles. Six bottles placed on a carrier are positioned below the filling station. The bottles are filled with a coloured liquid to a defined level. Once all bottles have been filled, the carrier is transported to the next station.

- Hands-on practice thanks to a use of industrial components

- Can be combined with any open-loop or closed-loop system from industry and education

- Can be expanded using additional IPA stations:

Compact station, mixing, corking and uncorking - Can be integrated into IMS® (Industrial Mechatronic System)

- Control along all three axes

- Modular design for quick and easy assembly

- Immediate application, thanks to hardly any need for wiring

The filling station consists of:

- 1 liquid tank

- Dosage unit for small quantities from 4…10 ml

- Supply tank

- Double-suction unit

Sensors:

- Capacitive sensors

- Flow sensors

- Magnetic sensors

Actuators:

- Positioning cylinder for X-axis

- Dosage cylinder

- Stop cylinder

- Motors

- Dosage pump

- 2/2-way process valves

- 3/2-way solenoid valve

- 4/2-way solenoid valve

- Compressed-air maintenance unit with pressure reducer and manometer

- Exhaust-air throttle valves

Electrical system:

- IMS connection DSUB 25