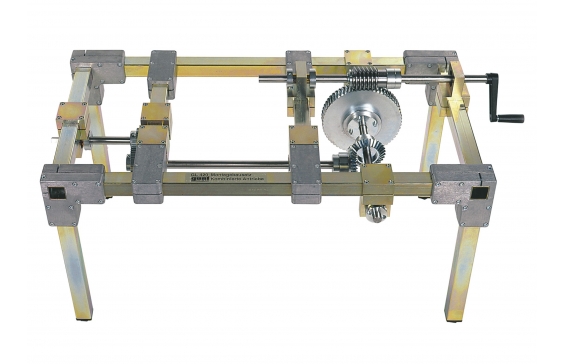

GL 420 Assembly combined gears

Different types of gear can be combined to achieve significantly altered transmission functions and new properties. The combination or interconnection can be done in series or in parallel. For example, several gear stages are often connected in series in order to achieve larger transmission ratios.

The GL 420 unit offers extensive exercises on the fundamentals of gear engineering. The unit focuses in particular on the practical assembly of gear components.

The exercise system can be used to configure six different gear types in various combinations. The setup of the components is flexible so that you can configure your own ideas and try out different gears.

Individual activities such as understanding the task and reading the drawing, assembling the components, adjusting, calibrating and checking the gear, and performing calculations are performed one after the other. The unit is driven by a hand crank. A solid frame made of square steel tubes and various bearings ensures sufficient accuracy to be able to set precise tooth interlocking. All components of the exercise system are ready at hand and securely housed in a storage system.

GUNT offers three assembly kits in this product range: from simple gears (GL 410) to combined gears (GL 420) and control gears (GL 430). Each assembly kit can be used completely independently of the other parts in the range.

- flexible and robust assembly kit for continuing mechanical gear engineering

- uses industrial components to represent the real world accurately

- quick and simple assembly

Toothed belt disk

- number of teeth: z=30, 32, 48, 60

Chain wheels

- number of teeth: z=20, 30

- DIN 8192 ISO 10B-1

Gear wheels

- number of teeth: z=30, 36, 50, 60

- module: m=2mm

Pair of bevel gears

- number of teeth: z=30

- module: m=3mm

- transmission ratio: i=1

- angle of rotation: 90°

- assembly, demonstration and experiments with combined gears

- two-stage belt drive

- chain gear with tensioning wheel and spur gear ratio

- two-stage spur gear

- combined bevel and spur gears

- combined worm and bevel gears

- rack-and-pinion drive with spur gear

- driven by hand crank

- uses industrial components

- solid, universal frame made of square steel tube

- familiarisation with main components and forms of mechanical gear engineering

- two-stage belt drive

- chain gear with tensioning wheel and spur gear ratio

- two-stage spur gear

- combined bevel and spur gears

- combined worm and bevel gears

- rack-and-pinion drive with spur gear

- calculations on mechanical gears

- practical setup of different gears, associated with setup and configuration exercises

- read and understand engineering drawings, familiarisation with technical terms