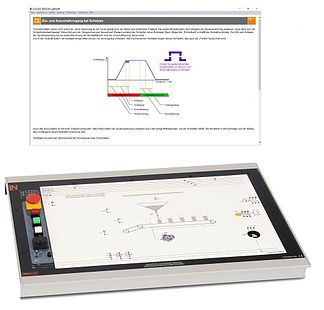

Course – Installation engineering 2: Control systems/protective circuitry

Experiment board for contactor controls with the following features:

· 4 Primary contactors

· 3 Motor protection switches

· 2 Auxiliary contactors

· 1 Universal time-delay relay

· 1 Current surge relay

· 6 Indicator lights

· 3 Limit switches

· 1 Emergency shut-down switch

· 3 Buttons

· 1 Manual-automatic switch

· 25 Project overlay masks

· Set of measuring leads and jumpers

· CD-ROM with LabSoft browser and course software

Familiarisation with control components

· Planning control projects

· Testing functionality with circuit simulators

· Function testing and troubleshooting in control projects

· Project contents:

Two-handed operation of a cutting machine (AND circuit)

Turning on a ventilator from various locations (OR circuit)

Self-latching pump control (dominant off)

Self-latching pump control (dominant on)

Pump control with contactor interlock

Pump control with inching circuit

Pump control with self-latching or inching circuit

Pump control with sequence control circuit

Drill control with external fan (sequence control circuit)

Direction control for a drill (simple reversing contactor circuit)

Sliding door control with button interlock

Crane control with direct change of direction

Crane control with delayed change of direction

Time-dependent conveyor-belt control

Time-dependent fan control

Manually controlled star-delta circuit

Automatically controlled star-delta circuit with no load

Automatically controlled star-delta circuit with load

Automatic star-delta reversing contactor circuit

Simple roller shutter control with safety bar

Enhanced roller shutter control with remote monitoring

Time-dependent speed control for Dahlander motors

Speed control for Dahlander motors

Immersion bath control

Pump control with current surge relays

· Course duration: 25 h approx.