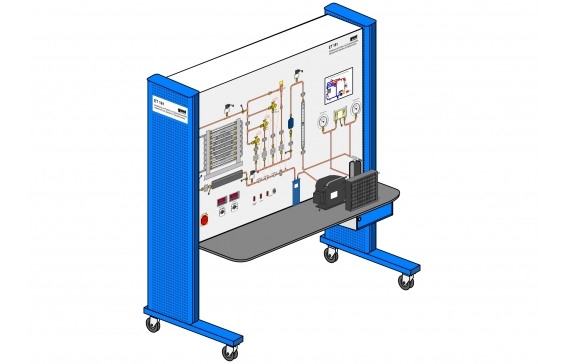

ET 181 Adjustment and operation of expansion valves

In the refrigeration circuit the expansion valves, also called primary controllers, also play an important role. The correct selection and adjustment decisively affects the capacity of the overall refrigeration system.

The trainer enables the investigation of four different expansion valves: TEV(Thermostatic Expansion Valve) with internal pressure compensation, TEVwith external pressure compensation, TEV with MOP function (Maximum Operating Pressure) and AEV (Automatic Expansion Valve). The expansion valves can be selected via valves.

Via an evaporator with glass tubes the correct injection and evaporation of the refrigerant can be monitored. An additional electrically heated superheater at the output of the evaporator enables the investigation of the control behaviour with different refrigerant superheating. The locations of the temperature sensor at the evaporator output can be selected. The control behaviour can be monitored at a flow meter. Pressure and temperature sensors upstream and downstream of the expansion valve and at the evaporator outlet provide information about the state of the refrigerant and the degree of superheating.

A commercial condensing unit completes the refrigeration circuit.

The measured values can be read on digital displays. At the same time, the measured values can also be transmitted directly to a PC via USB. The data acquisition software is included. In the software the control behaviour of the expansion valves is recorded over time. The trainee can check the correct adjustment of the expansion valve and investigate effects such as hunting.

- refrigeration circuit with different expansion valves

- adjustable superheating

- transparent evaporator to monitor the filling level and evaporation process

- recording of the control behaviour in the software

Air-cooled condensing unit

- power consumption: 485W at -10/32°C

- refrigeration capacity: 675W at -10/32°C

- receiver: 1,4L

Measuring ranges

- pressure: 2x -1…9bar, 1x -1…24bar

- temperature: 4 x -40…150°C

- flow rate: 3…41L/h

- trainer from the GUNT practical series for the training of mechatronics engineers for refrigeration

- refrigeration system with different expansion elements: thermostatic expansion valve TEV with internal pressure compensation, thermostatic expansion valve TEV with external pressure compensation, thermostatic expansion valve TEV with MOP function, pressure-controlled expansion valve AEV

- evaporator with glass tubes to monitor injection and evaporation

- valve downstream of the evaporator to simulate different pressure losses

- adjustable electric heater for superheating

- air-cooled condensing unit

- sensors record pressures, temperatures, flow rate

- refrigerant R134a, CFC-free

- GUNT software for data acquisition via USB under Windows 7, 8.1, 10

- operation and properties of the various expansion valves

- investigation of the static control characteristic

- investigation of the dynamic control behaviour

- adjustment of the optimum operating point

- benefits and disadvantages of the different expansion valves

- thermostatic expansion valve (TEV) with internal pressure compensation

- TEV with external pressure compensation

- TEV with MOP function (Max. Operating Pressure)

- pressure-controlled expansion valve (AEV)

- hunting effect