HL 630 Efficiency in heating technology

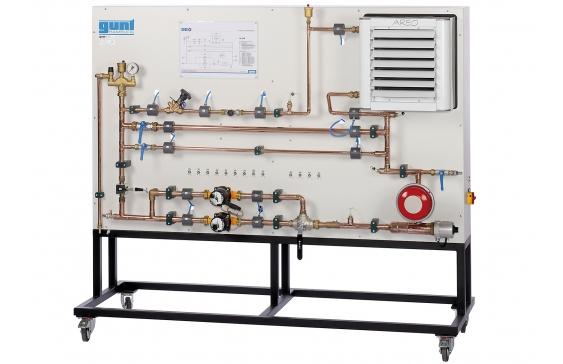

The trainer contains a complete closed heating circuit with circulating pump, electrical heater, convector for dissipating heat, various pipe sections, fittings and safety devices.

The losses of the most important fittings can be determined using seven differential pressure sensors. Control response and energy flux can be plotted using four temperature sensors, a flow rate sensor and an effective power sensor. The characteristics of a conventional circulating pump and a differential pressure controlled circulating pump can be compared.

The measured values are transmitted directly to a PC via USB and can be processed with the supplied software. Both circulating pumps, the heater and the convector fan can be controlled via PC.

- trainer with closed heating circuit

- trainer on mobile frame

- pumps, heater and convector fan, controlled via PC

Conventional circulating pump

- power consumption: 140W

- max. flow rate: 5m3/h

- max. head: 7m

Differential pressure-controlled circulating pump

- power consumption: 4…50W

- max. flow rate: 3,5m3/h

- max. head: 6m

Electric heater: 2000W

Expansion vessel: 2L

Software controller

- adjustable reference variable: 0…80°C

Measuring ranges

- differential pressure: 5x 0…600mbar, 2x 0…100mbar

- temperature: 0…100°C

- flow rate: 0…50L/min

- effective power: 0…200W

230V, 50Hz, 1 phase

- fundamentals of energy efficient heating technology

- closed water circuit with 2 circulating pumps, expansion vessel, heater and convector

- two-point and PID software controller for temperature: reference variable, hysteresis and PID parameters adjustable

- boiler safety group according to DIN 4751

- 7 differential pressure sensors, 4 temperature sensors, 1 effective power sensor and 1 flow rate sensor

- GUNT software with control functions and data acquisition via USBunder Windows 7, 8.1, 10

- familiarisation with a heating circuit

- familiarisation with temperature control

- two-point controller

- PID controller

- recording of step response

- recording of fitting and pump characteristics

- energy balances

- determining pump efficiency from hydraulic power and electrical power consumption

- heat transfer with convector (water-to-air heat exchanger with fan)

- comparison of circulating pumps

- conventional pump

- differential pressure controlled pump