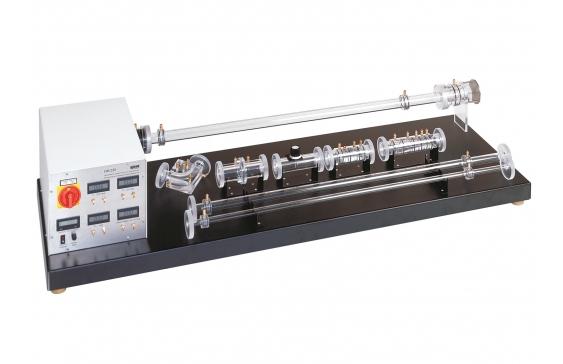

HM 230 Flow of compressible fluids

A radial fan with infinitely variable speed control draws in air from the environment. At the intake the air flow is accelerated in a measuring nozzle. Further down the measuring section the air flows through interchangeable measuring objects. Drawing in the air and the arrangement of the measuring objects on the intake side of the fan minimise turbulence when flowing into the measuring objects. All measuring objects are made of transparent material and provide excellent insight into the inner structure.

Pressure losses are studied in a pipe elbow, various pipe sections and a nozzle with sudden enlargement. The nozzle with gradual enlargement (de Laval nozzle) provides an introduction to the topic of transonic flow. The volumetric flow rate is measured in an orifice using a differential pressure manometer. The orifice is fitted with four interchangeable orifice disks for different measurement ranges. The fan’s characteristic curve can also be recorded by using a throttle valve.

The measured values for volumetric flow rate, pressure and speed are displayed digitally.

- investigation of flow in compressible fluids

- varied range of experiments for studying subsonic and transonic flow

- de Laval nozzle generates velocities up to Ma 1

Radial fan

- max. speed: 31000min-1

- max. volumetric flow rate: 226m3/h

- max. head: 318mbar

- max. power consumption: 1,8kW

Measuring objects

- pipe section: 1m

- Ø 16, 24, 34mm

- 90° pipe elbow

- 2 nozzles, inner diameter: 12…34mm

- with sudden enlargement

- with gradual enlargement (de Laval nozzle)

- orifice with orifice disks

- Ø 12, 19, 25, 32mm

- throttle valve: Ø 34mm

Measuring ranges

- speed: 0…99999min-1

- pressure:

- 1x 0…25mbar

- 1x 0…600mbar

- 1x 0…1000mbar

- velocity: 0…65m/s

230V, 50Hz, 1 phase

120V, 60Hz, 1 phase, 230V, 60Hz, 1 phase

UL/CSA optional

- investigate flow of compressible fluids

- subsonic and transonic air flow

- variable speed on the radial fan for adjusting the mass flow rate

- minimised turbulence by drawing in air and optimum arrangement of the measuring objects

- transparent measuring objects with connectors for pressure measurement provide insight into the internal structure

- measuring nozzle for determining the mass flow rate

- pressure losses in subsonic flow in pipe elbows and various pipe sections

- pressure curve at subsonic and transonic nozzle flow

- orifice for determining volumetric flow rate by differential pressure measurement

- record fan characteristic curve using a throttle valve

- digital displays for pressures, velocity and speed

- pressure losses in pipes and pipe elbows

- flow in convergent/divergent nozzles

- supersonic flow in the de Laval nozzle

- determine the speed of sound in air

- compare calculation methods for incompressible and compressible flow

- use complete continuity equation

- determine mass flow rate using nozzle and volumetric

flow rate using orifice - record calibration curve for orifice

- record fan characteristic curve at different mass flow rates and speeds