HM 240 Principles of air flow

HM 240 is part of a series that allows experiments on the fundamentals of air flow. The software for data acquisition and visualisation makes the experiments especially clear and enables fast execution of experiments with reliable results.

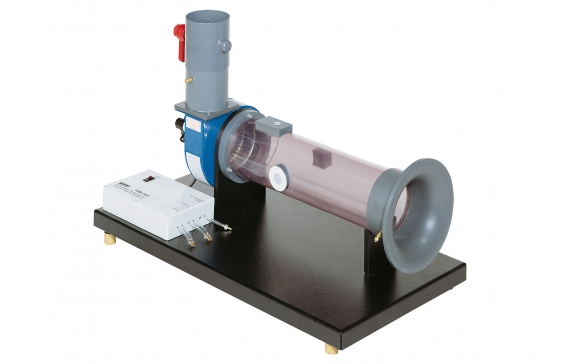

The experimental unit includes a radial fan, which can be used to generate flow velocities up to 9m/s. An inlet contour on the intake side ensures a low-turbulence flow and thus a homogeneous velocity distribution in the measuring section. A throttle valve on the end of the pressure pipe can be used to adjust the air flow to allow the fan characteristic curve to be recorded. When used in conjunction with the power meter HM 240.02 it is possible to determine the efficiency of the fan.

Further accessories for additional experiments can be attached in the intake pipe: electronic total pressure sensor HM 240.03, pressure distribution on a cylinder HM 240.04 and heat transfer at a cylinder in transverse flow HM 240.06. To study the friction losses, the intake pipe is replaced with pipe elements from HM 240.05 (straight pipes, pipe bends and pipe angles).

Measuring points along the measuring section allow temperature, pressure and velocity measurements to be taken. The flow rate is determined by means of the inlet contour and the pressure measurement. The measured values are transmitted directly to a PC via USB. The data acquisition software is included.

- wide range of accessories for basic experiments with air flow

- record a fan characteristic

- GUNT software for data acquisition

Radial fan

- max. power consumption: 90W

- speed: 2800min-1–

- max. flow rate: 460m3/h

- max. differential pressure: 480Pa

Delivery pipe

- outer Ø: 110mm

- inner Ø: 99,4mm

Intake pipe

- outer Ø: 140mm

- inner Ø: 134,4mm

Measuring ranges

- pressure: 1x ±10mbar

- pressure: 2x ±1mbar

- temperature: 0…200°C

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

- investigation of the principles of air flow

- transparent intake pipe with mounting options for additional accessories

- inlet contour minimises turbulence on the intake side

- throttle valve on the delivery pipe to adjust the air flow

- electronic measurement of temperature and pressure

- determine velocity by means of the dynamic pressure

- determine flow rate via differential pressure

- GUNT software for data acquisition via USB under Windows 7, 8.1, 10

- recording a fan characteristic

- in conjunction with the power meter HM 240.02

- determining the fan efficiency

- in conjunction with corresponding accessories

- velocity distribution in the pipe

- velocity distribution behind a cylinder subject to transverse incident flow

- pressure distribution around a cylinder subject to transverse incident flow

- friction losses in pipes, pipe bends and pipe angles

- recording the cooling curve of a copper cylinder subject to incident flow

- determining the heat transfer coefficients from the cooling curve