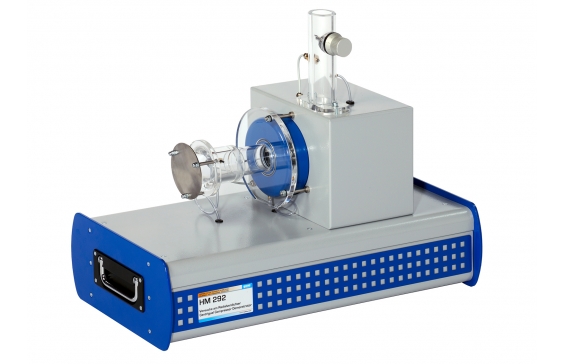

HM 292 Experiments with a radial compressor

Radial compressors are used to compress gases. The medium is drawn in axially to the drive shaft by the rotation of the rotor and flows through the rotor rotating at high speed. By means of centrifugal force, the medium is accelerated towards the outer edge and is compressed in this manner.

The experimental unit provides the basic experiments to get to know the operating behaviour and the important characteristic variables of radial compressors.

HM 292 features a two-stage radial compressor with variable speed via a frequency converter, an intake pipe and a delivery pipe. The intake and delivery pipes are transparent. A protective plate placed in front of the inlet of the intake pipe prevents larger objects from being drawn in or the clogging of the intake opening. The air flow is adjusted by a throttle valve at the end of the delivery pipe.

The experimental unit is fitted with sensors for pressure, temperature and speed. The flow rate is determinated via differential pressure measurement on the intake nozzle.

The microprocessor-based measuring technique is well protected in the housing. All the advantages of software-supported experiments and evaluation are offered by the GUNT software and the microprocessor. The connection to a PC is made by USB.

- illustrative model of a radial compressor

- transparent delivery pipe and intake pipe

- GUNT software for data acquisition, visualisation and operation

- part of the GUNT-Labline fluid energy machines

Intake pipe

- inner diameter: 44mm

Delivery pipe

- inner diameter: 34mm

Two-stage radial compressor

- power consumption: 1000W

- speed: 1000…16000min-1

- max. volumetric flow rate: 180m3/h

- max. pressure difference: 235mbar

Measuring ranges

- differential pressure (stage 1 / stage 2): 0…350mbar

- flow rate: 0…120m3/h

- temperature: 2x 0…100°C

- speed (compressor): 0…21000min-1

- electrical power consumption: 0…1000W

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase; 120V, 60Hz, 1 phase

UL/CSA optional

- functioning and operating behaviour of a radial compressor

- two-stage radial compressor with drive motor

- variable speed via frequency converter

- transparent intake and delivery pipes

- throttle valve for adjusting the air flow in the delivery pipe

- protecting plate at air inlet for undisturbed air flow

- determination of flow rate via intake nozzle

- display of differential pressures, flow rate, speed, electrical power consumption and hydraulical power output, temperatures and efficiency

- microprocessor-based measuring technique

- GUNT software with control functions and data acquisition via USBunder Windows 7, 8.1, 10

- operating behaviour and characteristic variables of a radial compressor

- recording of the compressor curve for both stages

- effect of the rotor speed on the pressure

- effect of the rotor speed on the flow rate

- distribution of stage pressure ratios

- effect of compression on the temperature increase

- determination of hydraulical power output and efficiencies