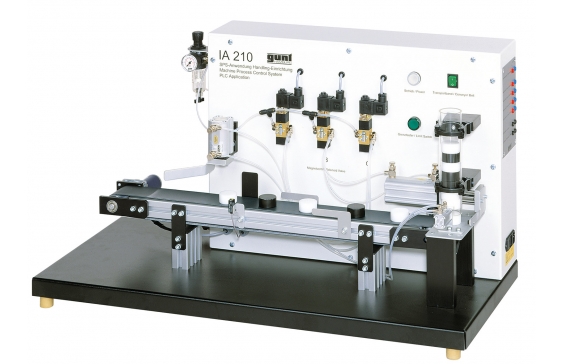

IA 210 PLC application: Materials handling process

IA 210 is a compact teaching and practice unit for the control of a materials handling process using a PLC. Two processes can be simulated: a punching process, or workpiece control in the form of a sort operation. All components are in a clearly laid out design.

Black and white cylindrical workpieces are fed from a container onto a conveyor belt. On the belt is a reflex photoelectric proximity switch which differentiates between light and dark and feeds the white items to the pre-selected process (punching or sorting). The black workpieces are always carried to the end of the belt, where they drop into a collector. Three 5/2-way solenoid valves, three double-acting cylinders and a pneumatic roller pushbutton can be operated via the PLC to execute the necessary steps: releasing the workpiece from the container; pushing the workpiece onto the conveyor belt; sorting or punching the workpiece. For punching, the workpiece is brought to a predefined position. The working cylinder can switch between sorting and punching modes by a simple sequence of actions.

The unit is designed for operation in conjunction with a PLC module. Use of PLC module IA 130 is recommended.

- automation fundamentals system

- handling demonstrator

- simulation of a punching process

- simulation of workpiece control

3 electrically operated 5/2-way valves

- with spring return

- with pilot valve

Reflex photoelectric proximity switch

- pnp, light-switching

- 5…150mm

Geared DC motor

- reduction ratio: 142,5:1

- nominal torque 5,92Nm

- nominal speed: 22min-1

Polyester weave conveyor belt

Workpieces, DxH: 40x20mm

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

120V, 60Hz, 1 phase

UL/CSA optional

- compact unit for experiments in the field of automation

- handling device with solenoid valves

- double-acting cylinder (15mm stroke): fixing / discharge of workpieces to container

- double-acting cylinder (80mm stroke): pushes workpiece onto conveyor belt

- double-acting cylinder (40mm stroke): executes the process (sorting or punching)

- conveyor belt with guide plates and DC motor

- cylindrical Plexiglas storage container holding 11 workpieces

- 15 workpieces made of Polyoxymethylene (POM): 10x white, 5x black

- pneumatic components fitted with quick-release couplings for 4mm hoses

- operation of actuators with compressed air

- lab jacks to external PLC

- set of laboratory cables and pneumatic hoses

- compressed air supply: max. 6bar, 3bar recommended

- familiarisation with and analysis of an automated materials handling process

- understanding and analysis of the mechanical, pneumatic and electrical functions

- familiarisation with the symbols, terms and modes of representation of pneumatic and electrical function diagrams

- familiarisation with automation components: cylinders, solenoid valves, photoelectric proximity switches

- familiarisation with the use of a PLC

- basic methods of programming

- adapting the program to the given handling process

- simulation of a punching process

- conveyor belt is stopped for punching

- conveyor belt also stops as soon as workpiece drops from belt end

- workpiece control simulation

- light-coloured workpieces are separated out; dark items reach the belt end