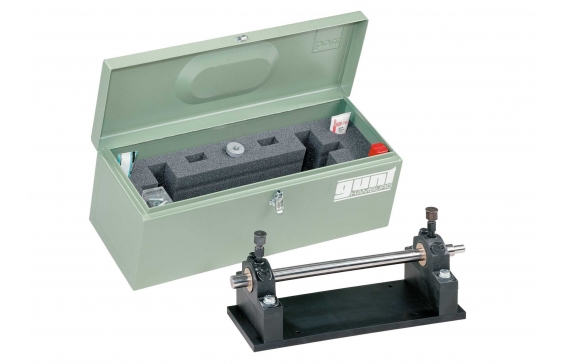

MT 170 Assembly shaft with journal bearings

Journal bearings execute a sliding motion between a bearing journal and a bearing shell. This sliding motion is usually lubricated by an intermediate medium. The damping effect of the lubricant in the bearing gap means journal bearings run particularly smoothly and quietly. Vibration and shock impact from gear wheels or crank mechanisms are also damped by journal bearings. They are widely used in piston engines, punches and presses as they are insensitive to high shock loads.

The MT 170 unit comprises a ground steel shaft and two horizontally split pedestal bearings. The journal bearings in MT 170 are grease-lubricated ones. Grease lubrication allows for a simple bearing construction. The upper bearing shell includes a lubrication fitting with a female thread to which a Stauffer lubricator can be screw-fitted by way of an intermediate pipe to supply the bearing with lubricant.

The face of the upper bearing shell, which is not subjected to load, contains a flat lubricating slot.

This distributes the grease over the full width of the bearing. The grease serves not only as a lubricant but also seals the bearing against external dirt and foreign bodies.

The MT 170 kit is part of the GUNT-Practice Line for assembly, maintenance and repair, which has been designed for technical colleges and company training centres. The close link between theory and practice-based learning content is evident.

MT 170 enables a simple journal bearing to be assembled and disassembled. Students become familiar with all the components and how they work. The individual parts are laid out clearly and are well protected in a tool box. The accompanying material details the individual steps involved in assembly, and provides additional information on the areas of application, mode of operation and design of the journal bearing.

- practical kit based on the assembly of a shaft / journal bearings arrangement

- part of the GUNT-Practice Line for assembly, maintenance and repair

Shaft

- Ø 25mm

- shaft journal for coupling: Ø 16mm

Materials

- pedestal bearing, bearing cap: grey cast iron

- bearing shells: red bronze to DIN 8221

- shaft: hardened and ground steel

- Stauffer lubricator: steel

- kit of a shaft with journal bearings

- part of the GUNT-Practice Line for assembly, maintenance and repair

- horizontally split pedestal bearing according to DIN 505, grease lubricated

- steel shaft, hardened and ground

- 2 pedestal bearings with split shells

- set of plastic strips to measure bearing clearance

- checking bearing alignment using touch-up paste

- complete set of tools for assembly

- journal bearing parts and tools housed in a sheet-steel tool box

- function and design of a simple journal bearing

- assembly and disassembly, including for the purposes of maintenance and repair

- measure the bearing clearance

- check the alignment

- read and understand engineering drawings and operating instructions

- together with MT 172

- investigate the running properties of the journal bearing