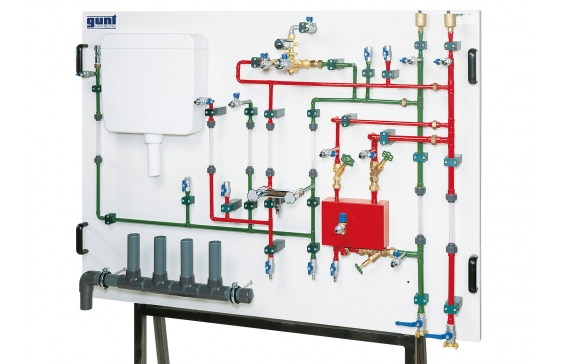

ST 320 Pipe cleaning training panel

The flushing process is intended to remove contaminants, for example the remnants of solder or sealant from the drinking water pipes. The individual pipe circuits must be flushed from bottom to top. It is possible to observe the flushing action by means of transparent pipe sections. Flushing is performed via two lines that are connected to a cold water supply. Contaminants are introduced into the pipe system through openings with shut-off valves.

Original plumbing components are used in the unit.

- pipe flushing according to DIN 1988 standards

- usage of original plumbing components

- contaminants can be introduced

Automatic mixer, thermostatic mixer

- recommended flow pressure: 1…5bar

- min. flow rate: 5L/min

- max. water temperature: 80°C, with temperature safety stop

Two handle mixer

Simulated hot water preparation

Safety fittings

- quick-action bleed valve

- safety valve on the hot water preparation unit

Pipes: Cu / transparent plastic

2x cold water connection: Geka coupling 1”

10x hose connection with quick-release coupling

- Pipe flushing in accordance with DIN 1988

- Cold water connection using hose

- Usage of original plumbing components

- Contaminants can be introduced into the pipe system via filling openings that can be shut off

- Transparent pipe fittings enable optimal observation of the flushing process

- Alternative accessories: flushing compressor (not included)

- introducing contaminants into the system

- limitations of flushing according to technical regulations