TM 210 Dry friction

Friction is a key factor in mechanical engineering. Static friction needs to be adequate to fix components to each other, such as parking brakes, self-locking threads and frictionally engaged connections. Dynamic friction needs to be kept as low as possible, such as on bearings, in guideways or in shaping tools. Consequently, great attention is paid to the topic in engineering mechanics, and understanding of it is enhanced by clearly laid-out experiments.

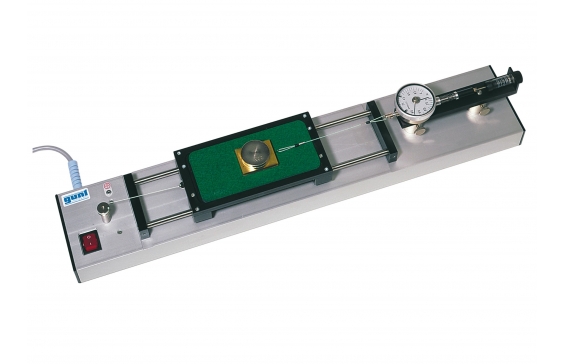

TM 210 provides a broad range of experiments relating to static and dynamic friction between solid bodies which are in contact with each other and moving relative to each other. Various influences on friction can be investigated, such as surface properties and material pairing.

A support friction surface slides beneath the stationary friction body. The support friction surface is held in a carriage which is drawn along by a motor at uniform velocity by a motor.

The friction body is connected to a height-adjustable force measuring unit. This ensures that the lines of action of friction force and tensile force are parallel. The force measuring unit is essentially a force gauge which is fitted with an air damper to compensate as far as possible for slip/stick effects and so indicate a mean friction force (with no spiking).

Three support surfaces and two friction bodies are available. The normal force can be varied by adding weights.

Experiments can be performed at two constant velocities. The air damping is adjustable. When it is inactive, slip/stick effects can also be observed.

All parts are clearly laid out and well protected on a storage system.

- fundamentals of mechanical friction

- stationary friction body, uniformly moving support friction surface

- force gauge with air damping cylinder

Support friction surface

- LxWxH: approx. 175x80x6mm

- aluminium

- PVC / felt

- glass

Friction body

- LxW: approx. 50x40mm

- dead-weight force: approx. 1N

- smooth / rough (Al), h=20mm

- brass / felt, h=5mm

Drive

- synchronous motor

- speed: 100min-1

- driving velocities: 23,5cm/min, 47cm/min

Force gauge with damper

- measuring range: 0…2N, graduation: 0,05N

Weights: 8x 0,5N

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase; 120V, 60Hz, 1 phase

UL/CSA optional

- mechanical friction between 2 solid bodies

- friction body stationary, support friction surface in a moving carriage

- 2 friction bodies each with 2 different surfaces

- 3 support friction surfaces with a total of 4 different surfaces

- carriage driven by cable pulley and motor

- 2 driving velocities via a graduated cable drum

- force measuring unit: force gauge and adjustable air damper

- force measuring unit height-adjustable

- lines of action of friction force and tensile force always parallel

- adjustable air damper – with damping: measurement of a mean friction force adjusted by disturbances, without damping: slip/stick effects measurable

- storage system to house all parts

- difference between static and dynamic friction

- friction forces as a function of

- normal force

- sliding velocity (relative velocities of the friction partners)

- material pairing

- surface properties of the friction partners

- size of the contact area

- slip/stick effect

- determination of friction coefficients