TM 260.05 Dynamic friction in cylindrical pin – roller

In bearing and drive technology, dynamic friction occurs at the sliding and rolling points, which leads to power losses in the technical systems. Dynamic friction is differentiated into sliding, rolling and spinning friction. In dynamic friction, there is relative translation between the two bodies.

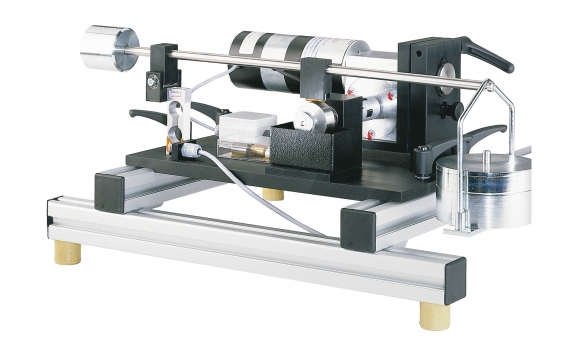

The tribological system in TM 260.05 allows a clear representation of the dynamic friction and an analysis of the frictional forces. The experimental unit contains a fixed cylindrical pin that is pressed radially against a rotating roller as the friction pair. There is point contact between the friction partners. The contact force between the friction partners can be adjusted gradually up to a maximum of 80 N by means of a lever. The experimental unit includes a tank that supplies lubricant.

Different lubrication conditions can be studied, such as dry friction, water or oil lubrication. Cylindrical pins made of different materials are included in the scope of delivery to study different friction pairings.

The TM 260 drive unit is required in order to conduct experiments. The experimental unit is mounted quickly and easily on the frame of the drive unit with quick-action chucks. The roller is driven by a clampable coupling between drive unit and gear unit. The display and control unit of the drive unit shows frictional force and speed and allows the continuous adjustment of the speed.

The frictional force and the coefficient of friction can be determined in experiments. The frictional forces are measured by a force sensor.

- frictional forces between two sliding friction pairs

- investigation of wear

- use of different lubricants possible

Load application device

- max. load: 80N

- lever arm ratio: 2:1

Roller

- Ø=40mm

- hardened stainless steel, ground

Cylindrical pin, ØxH: 10x20mm

- 3x aluminium

- 6x brass

- 6x steel

Force sensor for frictional force

- 0…50N

Weights

- 1x 5N (hanger)

- 1x 20N

- 1x 10N

- 1x 5N

- frictional forces in cylindrical pin and roller that slide on each other (point contact)

- quick and easy assembly of the experimental unit on the frame of the drive unit

- rotating roller made of hardened and ground stainless steel

- roller is driven by a clampable coupling between drive unit and gear unit

- fixed cylindrical pin made of different materials: aluminium, brass or steel

- load on the cylindrical pin via lever arm and stepped weights

- use of different lubricants, e.g. oil or water

- frictional force measured by force sensor

- displays of force and speed and speed adjustment on the drive unit

together with the drive unit

- frictional forces in different friction pairs and loads

- frictional forces with different lubrication

- frictional forces at different relative speeds of the friction partners

- wear under different friction parameters