WL 220 Boiling process

Heating a liquid over a heating surface produces different modes of boiling dependent on the heat flux density. They can accelerate the evaporation process (nucleate boiling) or impair it (film boiling). In practice, a limitation of the heat flux density must be assured in order to prevent damage to the heating surface. This knowledge is applied in practice e.g. when designing steam boilers for steam-powered drives.

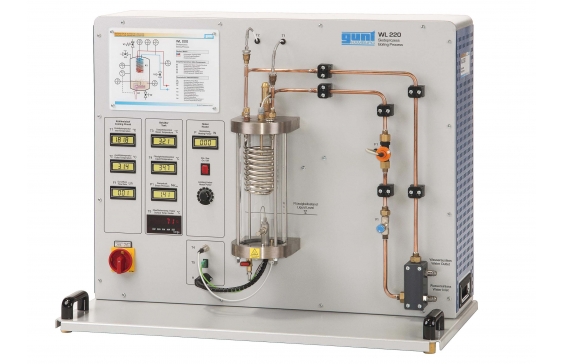

The WL 220 experimental unit can be used to demonstrate boiling and evaporation processes in a straightforward manner. The processes take place in a transparent tank. A condenser in the form of a water-cooled tube coil ensures a closed circuit within the tank. Solkatherm SES36 is used as evaporating liquid. Compared with water, this liquid has the advantage that its boiling point is at 36,7°C (1013hPa), whereby the evaporation process takes place at much lower temperatures and a lower heating power.

Sensors record the flow rate of the cooling water, the heating power, pressure and temperatures at all relevant points. The measured values can be read on digital displays. At the same time, the measured values can also be transmitted directly to a PC via USB. The data acquisition software is included.

- visualisation of boiling and evaporation

- software for data acquisition

Heater

- power: 250W, continuously adjustable

Safety valve: 2bar rel.

Pressure vessel: 2850mL

Condenser: coiled tube made of copper

Measuring ranges

- tank pressure: 0…4bar abs.

- power of heater: 0…300W

- flow rate (cooling water): 0,05…1,8L/min

- temperature: 4x 0…100°C

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

120V, 60Hz, 1 phase

UL/CSA optional

- visualisation of boiling and evaporation in a transparent pressure vessel

- evaporation with heating element

- condensation with tube coil

- safety valve protects against overpressure in the system

- pressure switch for additional protection of the pressure vessel, adjustable

- sensors for pressure, flow rate and temperature with digital display

- GUNT software for data acquisition via USB under Windows 7, 8.1, 10

- CFC-free evaporating liquid Solkatherm SES36

- visualisation of different forms of evaporation

- free convection boiling

- nucleate boiling

- film boiling

- heat transfer

- effect of temperature and pressure on the evaporation process