WL 315C Comparison of various heat exchangers

In practice, different types of heat exchanger are used depending on requirements in order to ensure efficient heat transfer and avoid losses.

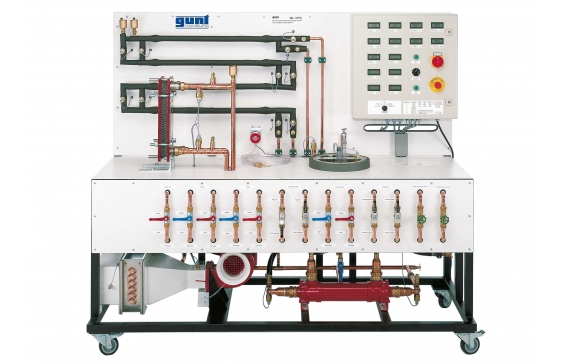

The WL 315C trainer is used to study and compare five different heat exchangers. Both parallel flow and counterflow operation are demonstrated, with their different temperature curves.

In the plate, tubular and shell & tube heat exchangers, heat is transferred between hot and cold water in tubes or between plates. In the finned tube heat exchanger, the air flows around pipes with hot water in crossflow.

In the stirred tank with double jacket and coiled tube, either the outer jacket or the inner coiled tube can be filled with hot water. A stirring machine ensures that the water inside the tank is mixed to achieve an even heat distribution.

The air volume flow for studying the finned tube heat exchanger is adjusted via a throttle valve at the fan outlet. Valves are used to switch between parallel flow and counterflow. The flow rate in the hot water or cold water circuit can also be adjusted by means of valves.

The air volume flow is measured with a fixed differential pressure sensor. The water pressure can be measured at different points using a portable differential pressure sensor. Temperatures and flow rates are also measured. The measured values are read from digital displays and can be transmitted simultaneously via USB directly to a PC where they can be analysed using the software included.

Hot and cold water is supplied either from the laboratory network or by means of the accessories WL 312.10 hot water generator and WL 312.11 water chiller.

- use of industrial components

- five different heat exchangers in comparison

- adjustment of operating modes and selection of heat exchangers clearly arranged on the front panel

Plate heat exchanger, (water-water)

- number of plates: 10

- heat transfer area: approx. 0,26m2

- output: 15kW

Tubular heat exchanger (water-water)

- heat transfer area: 0,1m2

Shell & tube heat exchanger (water-water)

- output: 13kW

Finned tube heat exchanger (water-air)

- heat transfer area: approx. 2,8m2

- fan max. flow rate: 780m3/h

- fan max. pressure difference: 430Pa

Stirred tank with double jacket and coiled tube (water-water)

- double jacket heat transfer area: 0,16m2

- coiled tube heat transfer area: 0,17m2

Measuring ranges

- differential pressure:

- 1x 0…10mbar (air)

- 1x 0…1000mbar (water)

- flow rate:: 2x 0…3m3/h

- temperature:: 10x 0…100°C

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase; 120V, 60Hz, 1 phase

UL/CSA optional

- investigation and comparison of five different heat exchanger types

- parallel flow or counterflow can be set via valves

- flow rates can be adjusted via valves

- electromagnetic flow meter for hot and cold water

- portable differential pressure sensor for water

- fixed differential pressure sensor for air, to determine the volumetric flow rate

- digital displays for temperature, pressure differences and flow rate

- hot water generator and water chiller available (WL 312.10 and WL 312.11)

- GUNT software for data acquisition via USB under Windows 7, 8.1, 10

- familiarisation with heat transfer processes

- heat transfer

- heat conduction

- determination of the heat transfer coefficient

- creation of temperature curves for the different heat exchangers

- parallel flow

- counterflow

- cross parallel flow

- cross counterflow

- comparison of the different heat exchangers between each other

- plate heat exchanger

- tubular heat exchanger

- shell & tube heat exchanger

- finned tube heat exchanger

- stirred tank with double jacket and coiled tube