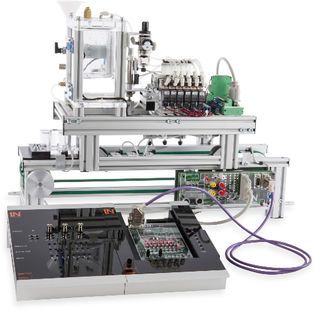

IPA 3 FILLING STATION

Enabling a filling of bottle groups in defined doses, this station is the optimum solution for typical production processes in the most varied of industries. The system’s modularity permits various configurations to be implemented in a safe laboratory environment.

| ADDITIONALLY REQUIRED: | ||||

|---|---|---|---|---|

| 1 |

|

25-pin serial interface cable, Sub-D plug/socket | LM9061 | |

| ADDITIONALLY RECOMMENDED | ||||

|---|---|---|---|---|

| 1 |

|

Compressor, low-noise | SE2902-9L | |

| 1 |

|

Tubing and accessory set for mechatronics systems | LM9670 | |

|

In areas where there are high levels of humidity the membrane dryer with water trap should be used to avoid condensation: |

||||

| 1 |

|

IDG3 membrane dryer with rapid coupling and filter AF20 with water trap | LM9671 | |

| IMS FURNITURE | ||||

|---|---|---|---|---|

| 1 |

|

SybaPro mobile IMS experiment trolley, 1200mm | ST7200-3U | |

- Setup, wiring and start-up of a process plant

- Selection, application and connection of various sensors

- Measurement of electrical and process variables such as filling level

- Use and connection of measurement transducers

- Design of open-loop and closed-loop control programs

- Process handling and monitoring

- Inspection, maintenance and repair

- Networking of process plants